About

Our mission is to bridge the gap between sustainability and scale by providing researchers and farmers with reproducible, lightweight robotics that reduce labour and environmental impact without proprietary dependencies.

The Sowbot Open AgBot ecosystem is designed to bridge the “prototype gap” in agricultural robotics. It provides a Reference Hardware Design that is accessible to startups and is developing a Production-Ready Software Stack that satisfies the rigorous requirements of research.

For startups, this eliminates ~18 months of R&D on the “plumbing” (drivers, networking, UI), allowing them to focus on their unique value (e.g., a proprietary seeding algorithm). For researchers, it provides a stable, repeatable environment where experiments can be shared across labs by simply sharing a Docker image.

Check the Roadmap on Github

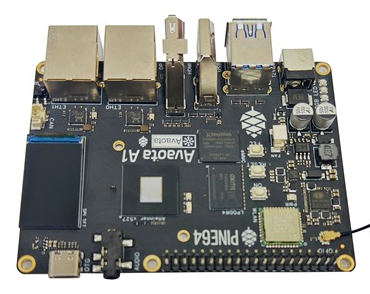

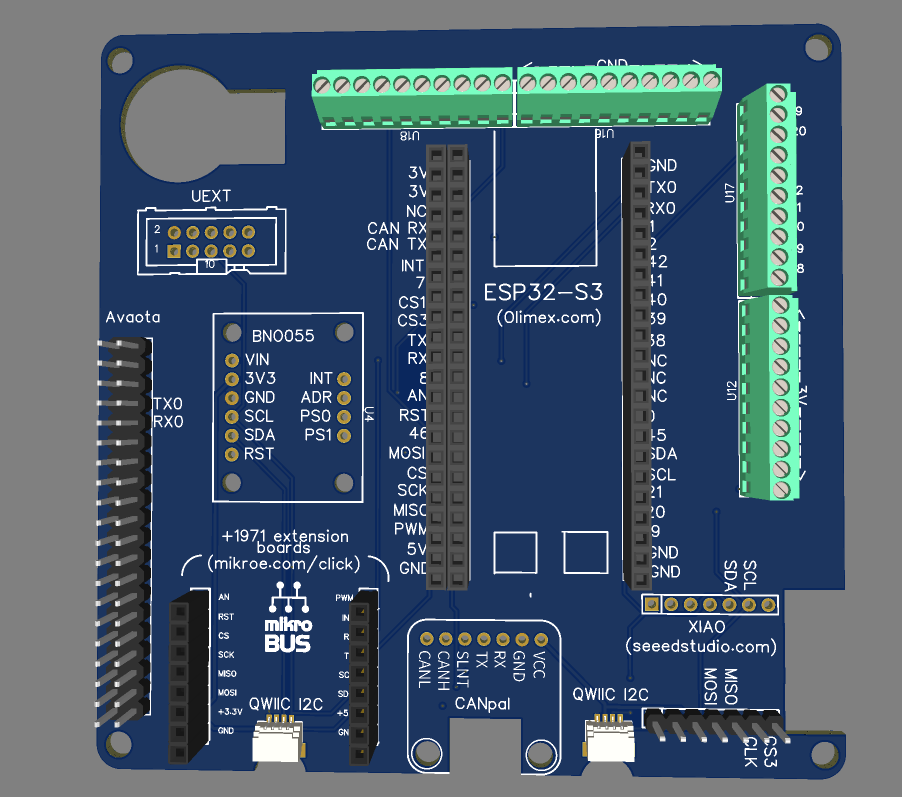

Open Core: The robot ‘brain’

Status: Largely fabricated/ constructed, ESP32 carrier needs some work

A fully open-hardware robot compute unit built around a stackable 10 cm × 10 cm module standard with two Avaota A1 SIngle Board Computers (SBC) connected via a single ethernet cable.

Board A: Control & Safety

Board A is the primary controller responsible for the robot’s physical integrity and movement.

Core Tasks: ROS 2 navigation stack, topological mapping, and EKF localization.

Hardware: Direct serial link to the ESP32 (Lizard firmware) for motor control and safety watchdogs, for deterministic real-time control.

Priority: Executes real-time path planning and emergency stop logic.

Board B: Perception & AI

Board B acts as a dedicated vision processor for compute-heavy tasks.

Core Tasks: Camera drivers, image pre-processing, and neural network inference (e.g., YOLO).

Output: Processes raw video into lightweight detection coordinates or semantic labels.

Priority: High-bandwidth data handling without impacting SBC A’s CPU stability.

Native CAN bus support enables robust field-level communication. Dual GNSS RTK receivers provide centimetre-scale positioning for navigation and task execution.

All schematics, PCB layouts, and firmware are released under open licences. The system is housed in a rugged, waterproof aluminium enclosure with M12 connectors, designed for long-term outdoor deployment.

| Photo | Component | Description | Qty |

|---|---|---|---|

|

Yuzuki Avaota-A1 SBC |

Octa-core 64-bit ARM Cortex-A55 (up to 1.8 GHz), 4 GB RAM, integrated AI accelerator. Open-hardware platform. | 2 |

|

ESP32-S3 Microcontroller |

Real-time Lizard control node and general-purpose peripheral I/O on custom open hardware PCB. | 1 |

|

BNO055 IMU |

Adafruit 9-DOF Absolute Orientation IMU Fusion Breakout – BNO055 | 1 |

|

CAN Bus Breakout |

CAN interface breakout for deterministic, vehicle-grade communication. | 1 |

|

SparkFun GNSS RTK or Septentrio Mosaic |

High-precision GNSS positioning with RTK support. | 2 |

|

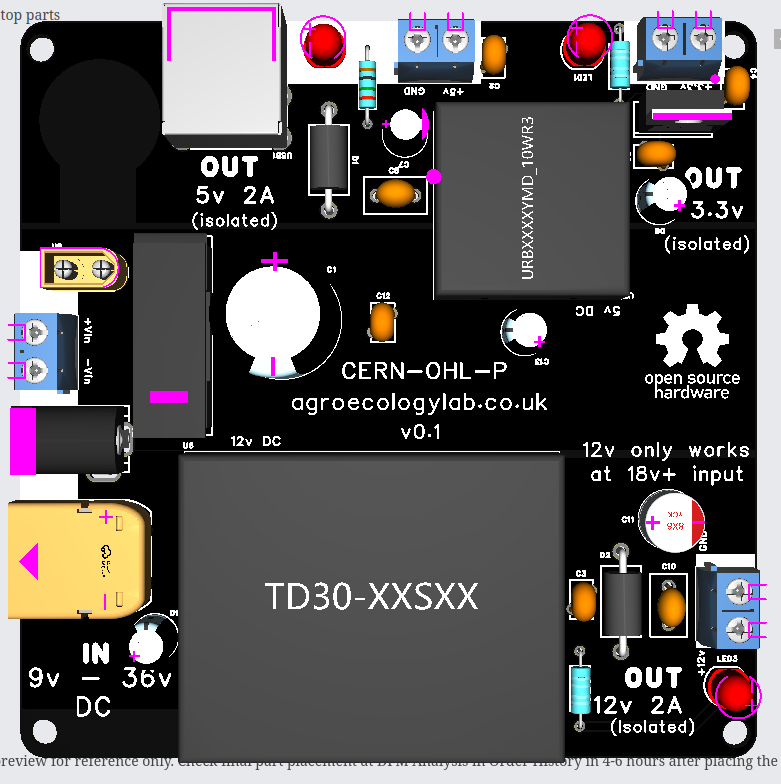

36V → 12V & 5V Power Conversion & Isolation |

Custom-fabricated power regulation and electrical isolation board. | 1 |

|

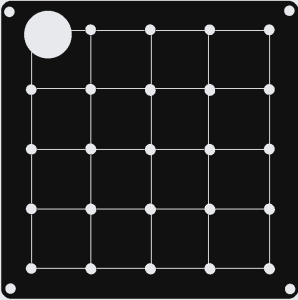

Simple mount plate |

10cm x 10cm mount plate with 20mm holes | 1 |

|

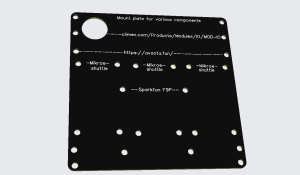

Avaota/RTK mount plate |

10cm x 10cm mount plate with holes for components | 1 |

|

Waterproof Aluminum Enclosure |

Sealed aluminum enclosure with M12 connectors for rugged deployments. | 1 |

|

16mm Estop/Switch |

16mm estop/switch | 1 |

|

Cable for switch |

Cable to connect to estop | 1 |

|

16mm Cable glands |

16mm Cable glands | 1 |

|

Cable blank cap |

16mm &10mm Cable blank | 1 |

|

XT60 inline fuse |

XT60 inline fuse | 1 |

| DC barrel splitter |

Power two Avaota | 1 |

—————-

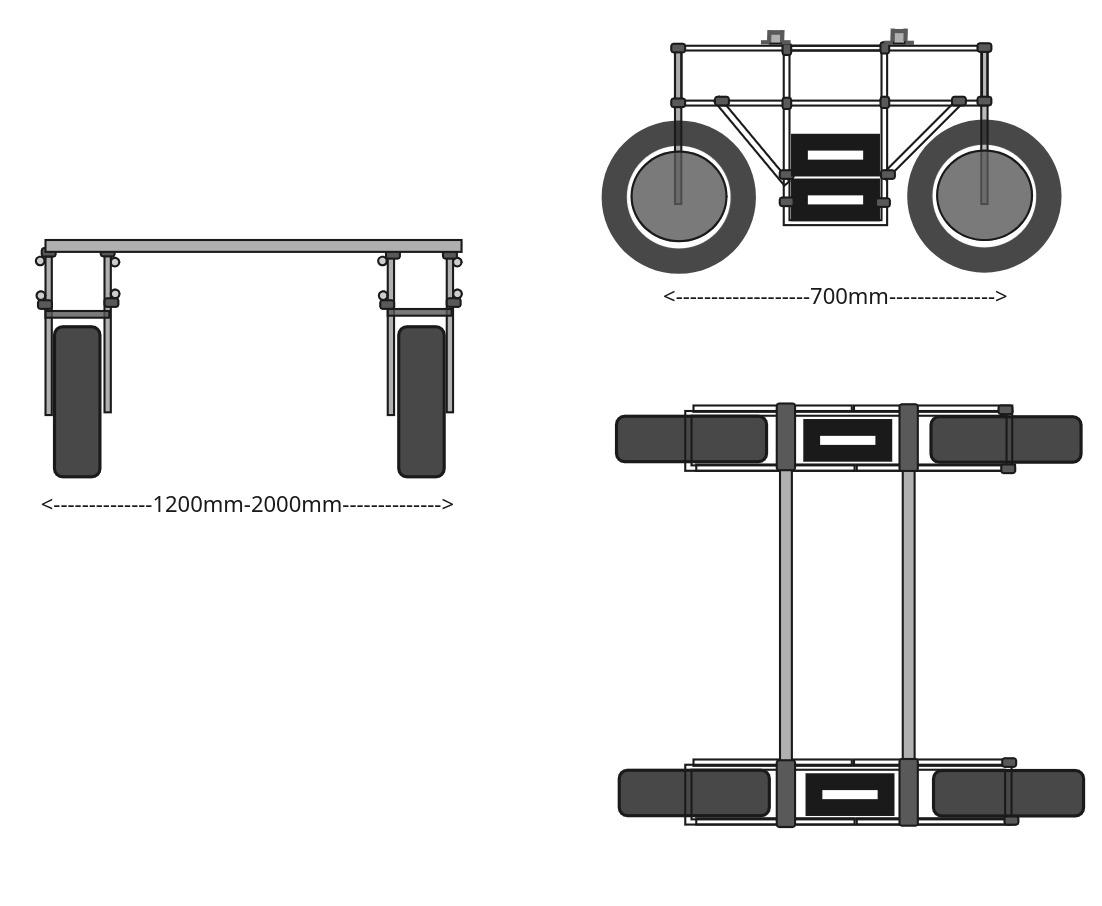

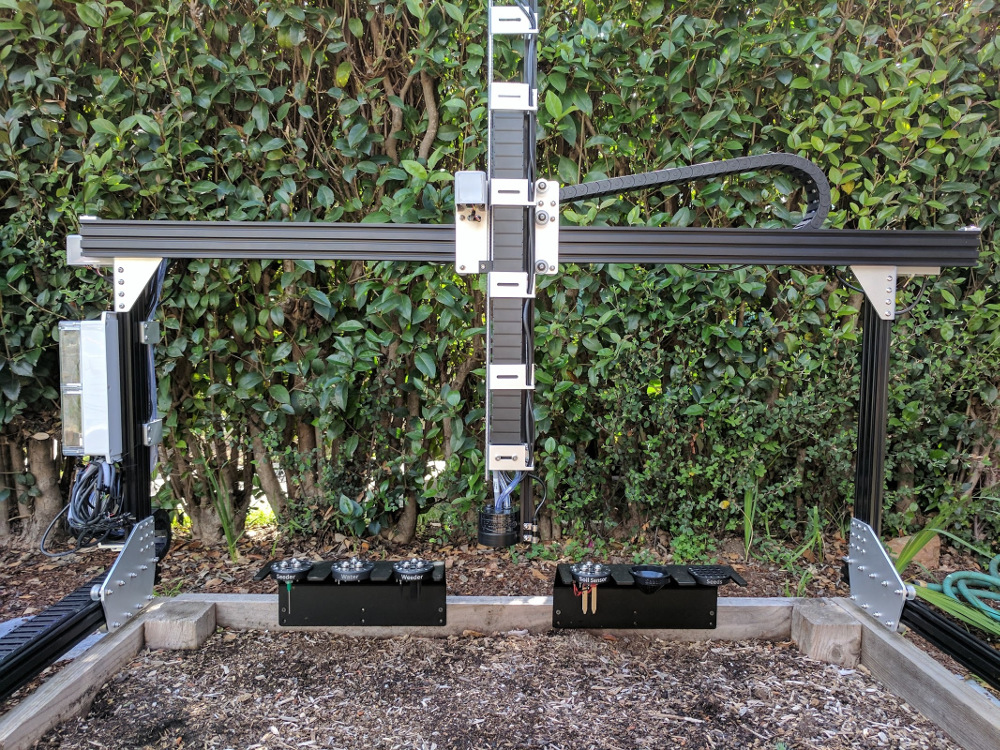

Sowbot: The body

Status: Detailed BOM & concept but not yet assembled

The Open core module above powers the Open AgBot reference platform. This integrates high-performance motors, precise control, long-lasting batteries suitable for Low temp <0C charging and rugged suspension into a fully modular, open-hardware agricultural robot.

Modular chassis and standardised connections enable rapid expansion and reconfiguration, providing full control over electronics, software, and mechanics for a versatile, field-ready system.

| Photo | Component | Description | Qty |

|---|---|---|---|

| Odrive CAN Bus Drivers with (Open hardware version, in development) Later migration to SimpleFOC hardware possible | High-performance motor control with real-time CAN communication for precise torque and speed regulation. | 2 | |

|

800W Hub motor |

14.5″ Geared hub motors 100N.m with 4096*10 encoder delivering good acceleration and traction. | 4 |

|

12V 80Ah Sodium-Ion Battery Packs |

High-capacity energy modules providing long-duration power for fully autonomous operation. | 6 |

|

5″ Fatbike Suspension Forks |

Shock-absorbing suspension for smooth navigation across rough terrain and dynamic environments. | 4 |

|

Modular Chassis Structure |

Lightweight aluminium tube sections forming a flexible backbone for sensors, processors, and actuators | Many |

|

Chassis Connectors |

Aluminium 90° crossover and modular pipe fittings used to join tubing at right angles for structural frames. | Many |

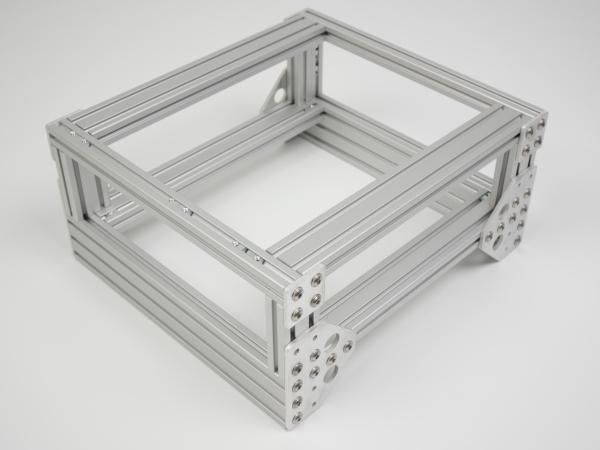

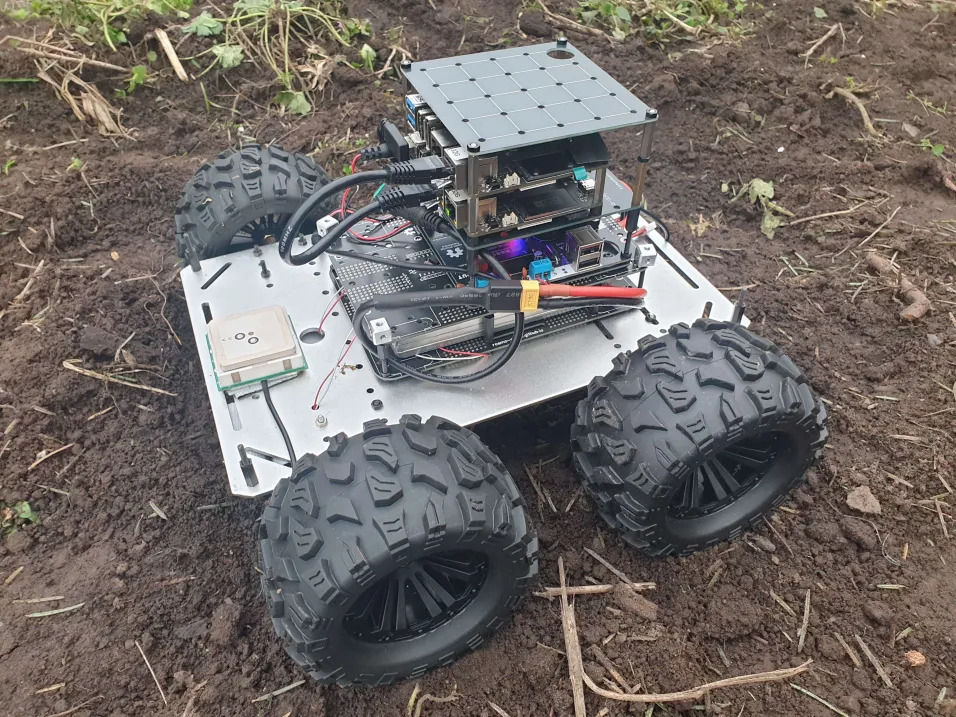

Sowbot Mini

(dev platform)

Status: Needs assembly and testing

A 1/4 scale development platform for testing and validation

| Dev platform Components | Description | Quantity |

|---|---|---|

| Driver | Odrive |

2 |

| Electric wheel | 6.5″ hub with encoder |

4 |

| Chassis structure | 1515 extrusion |

many |

| Chassis connections | 1515 corner | Many |

Sowbot Pico

(dev platform)

Status: Requires some Lizard firmware work, but physical platform tested with alternate software

Track issue here

| Photo | Component | Description | Qty |

|---|---|---|---|

| 12V 37RPM DC Motor |

DC 12V, 37RPM output, high-torque speed reduction gearbox Reversible via polarity swap. with encoders ~$25US | 4 | |

| 3S Lipo |

DC ~11.4V, largest capacity you can afford ~$25US | 1 | |

| 125mm / 70mm Wheels |

125mm outer diameter, 70mm wide. Supplied as a 2-piece set. ~$25US | 2 | |

| chassis |

128mm x 194mm ~$17US | 2 | |

| 3S USB lipo charger |

Charger for battery ~$5 | 1 | |

| XT60 splitter 1Male > 2 Female |

Cable splitter ~$4 | 1 | |

| Zio 4-Channel DC Motor Controller (Qwiic) |

Dual H-bridge bidirectional motor controller supporting 4 DC motor outputs (2 independent channels), 2.5–13.5V supply, 1.2A continuous / 3.2A peak. I²C Qwiic-compatible for easy daisy-chaining. Supports CW, CCW, brake, and stop modes via PWM. $14 | 1 | |

| XT60 > Screw terminal |

XT60 male > Screw | 1 | |

| 22 AWG PH 2.0 cable |

PH 2.0 cable | 1 |

A 3d print body is possible